Lihlahisoa

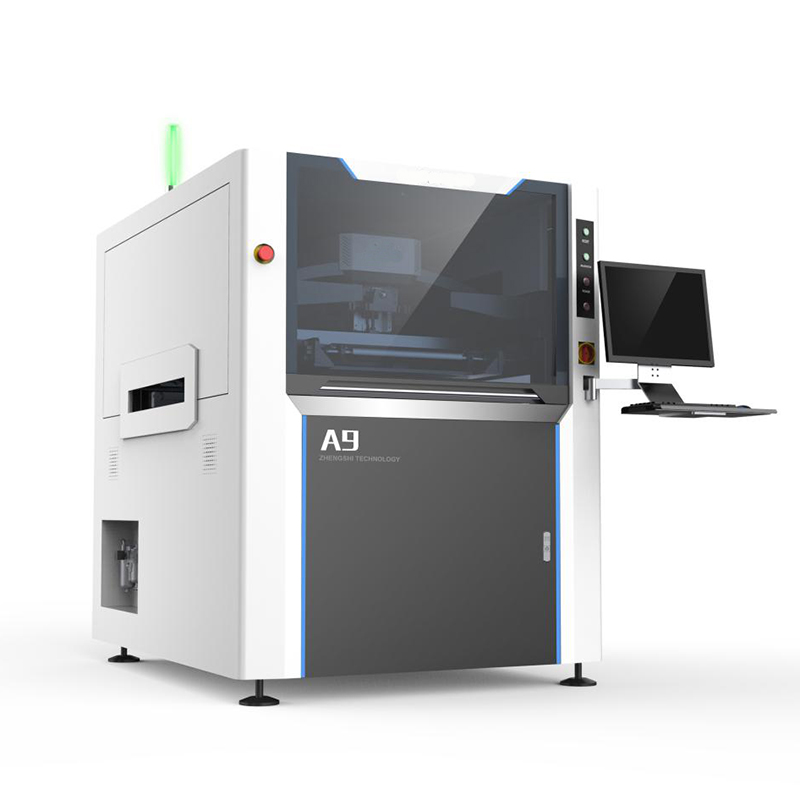

SFG Automatic Solder Paste Printe A9

Molemo

● Mofuta oa borokho ba arch o emisang scraper e hokahaneng ka kotloloho.

● Hlooho ea ho hatisa ka mochine o khonang ho etsoa le ho emisa mochine o itlhophisang oa stepper.

● Mofuta oa selaete oa mabili a mane o nang le li-slide tse peli tse peli o netefatsa ho nepahala le ho tsitsa ha scraper e leba pele le morao.

● Sistimi e ikhethang ea phetisetso ea lebanta e qoba ho ts'oaroa kapa ho oa ho PCB.

● Enjene e ka reroang e laola lebelo la lipalangoang 'me e beha PCB sebakeng se nepahetseng.

● Sehlopha sa ho hloekisa se arohane le khamera ea CCD, e ka fokotsang mojaro oa motlakase le tšusumetso, ho ntlafatsa boemo bo nepahetseng le lebelo le ho lelefatsa bophelo ba tšebeletso.

● Ka servo motor le lead screw, sethaleng se tobileng sa khokahanyo ea UVW se hlahisoa ka ho nepahala ho phahameng, ho tiea ho phahameng le mohaho o kopanetsoeng.

Litlhaloso

| Liforeimi tsa skrine | Min Size | 470 × 370 limilimithara |

| Boholo bo boholo | 737 × 737 limilimithara | |

| Botenya | 25-40 limilimithara | |

| PCB Min boholo | 50 × 50 limilimithara | |

| PCB Max Size | 510 × 340 limilimithara | |

| Botenya ba PCB | 0.4-6 limilimithara | |

| Leqephe la ntoa la PCB | <1% | |

| Bophahamo ba Lipalangoang | 900±40mm | |

| Tataiso ea Lipalangoang | Ho le Letshehadi-Ka ho le letona;Ho le letona-Ho le Letsedi;Ho le Letshehadi-Letshehadi;Ka ho le letona-Le letona | |

| Lebelo la Lipalangoang | Max 1500mm/s (E ka khonahalang) | |

| Board Location PCB | Sistimi ea Ts'ehetso | Tafole ea Magnetic Pin/Ho ea holimo e lokisitsoe /support block |

| Sistimi ea Clamping | Ho koala ka lehlakore, nozzle ea vacuum, Khatello ea Z e ka khutlisoang ka boits'oaro | |

| Hlooho ea Mohatisi | Lihlooho tse peli tse ikemetseng tsa khatiso ea enjene | |

| Lebelo la Squeegee | 6 ~ 200mm / sec | |

| Khatello ea Squeegee | 0-15 lik'hilograma | |

| Squeegee Angel | 60°/55°/45° | |

| Mofuta oa Squeegee | Tšepe e sa hloekang (e tloaelehileng), polasetiki | |

| Stencil Karohano Lebelo | 0.1 ~ 20mm/sec (E ka khoneha) | |

| Mokhoa oa ho hloekisa | Dry, Wet, Vacuum (Ea khoneha) | |

| Mekhahlelo ea Litokiso tsa Letlapa | X:±10mm;Y:±10mm;θ:±2° | |

| Tlhahlobo ea Solder Paste | Tlhahlobo ea 2D(E Tloaelehileng) | |

| Pheta Ho Nepaha ha Boemo | ± 0.008mm | |

| Ho Nepaha ha Khatiso | ± 0.02 limilimithara | |

| Nako ea Cycle | <11s (Kantle ho Printing & Cleaning) | |

| Phetoho ea Sehlahisoa | <5Metsotso | |

| Moea o Hlokahala | 4.5 ~ 6kg/cm2 | |

| Kenyeletso ya Matla | AC:220±10%,50/60HZ,3KW | |

| Mokhoa oa ho laola | Taolo ea PC | |

| Litekanyo tsa Mochini | 1220 (L)×1530 (W)×1500(H)mm | |

| Boima ba Mochini | Hoo e ka bang: 1200kg | |

Selelekela

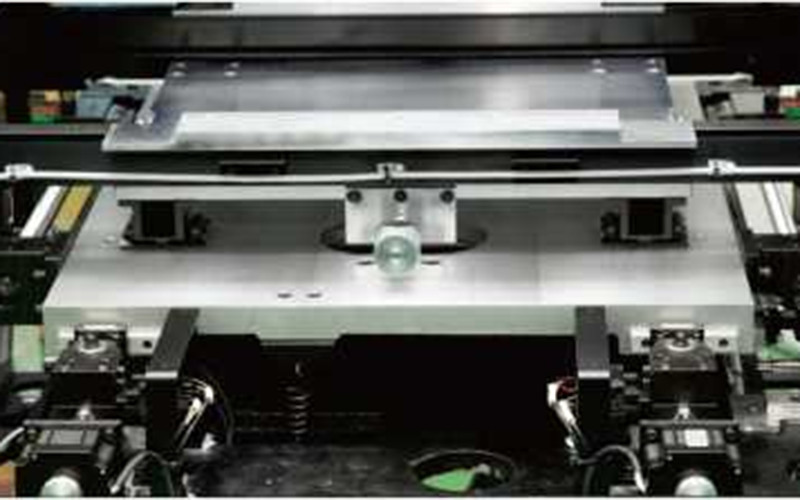

● Scraper System

Arch borokho mofuta suspending ka ho toba kgokagantswe scraper Printa hlooho ka programmable le suspending ho intša fetola stepper motor drive.Four mabili positioning slide mofuta le bilateral double slider etsa bonnete ba ho tsamaea ho nepahala le botsitso ha scraper matha pele le pele. lihlooho li khannoa ka ho latellana ke li-motor tse peli tse phahameng tse nepahetseng tsa stepper, ho netefatsa ho nepahala le ho tsitsa ha khatello.Sistimi e koetsoeng ea ho laola khatello ea loop e ka lemoha ka nepo le ho laola khatello ea squeegee nakong ea tlhahiso ea nako ea sebele.

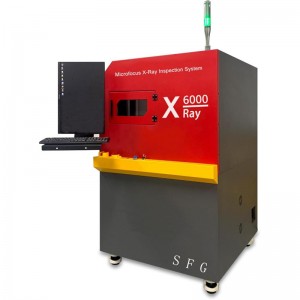

● Setšoantšo le Tsamaiso ea Optical

Leseli le le leng le le leng, khanya e phahameng ea coaxial le tsamaiso ea pono e tsoetseng pele ka holimo / ka tlaase. Mefuta eohle ea matšeliso a khanyang, e ikemetseng le e nepahetseng ea mefuta eohle ea lintlha tsa MARK.E sebetsa bakeng sa ho roala tin, koporo, ho roala khauta, ho fafatsa ka tin, FPC le mefuta e meng ea PCB e nang le mebala e fapaneng, e khonang ho netefatsa ho nepahala ho phahameng.

● Mokhoa oa ho Hloekisa

Sistimi ea ho hloekisa ea stencil e iketselitse ebile e sebetsa.Likhetho tse tharo tsa ho hloekisa ka mokhoa o omileng, ho hloekisa metsi le Vacuum deaning li ka khethoa ho sebelisoa, ka bonngoe le ho atisa.'Me u ka boela ua khetha ho dean ka letsoho.The unit to dean e arotsoe ho CCD camera, e ka fokotsang mojaro oa enjene le ts'usumetso, ea ntlafatsa boemo bo nepahetseng le lebelo le ho lelefatsa bophelo ba ts'ebeletso.Sprinkler e tiisa ho fafatsa ka ho lekana, ho tloha holimo ho ea tlase. software mosebetsi o ka laola lethal dose ea joala le stencil ho hloekisa pampiri, ka Ka katleho boloka consumables.Vacuum hloekisa e tšehetsoa ka fan e inehetseng, e matla le e sebetsang.

● Sistimi e nepahetseng ea ho lekanya sethala se khethehileng

Khokahano ea lilepe tse tharo e entsoe ka litšoaneleho tse matla tse phahameng haholo.lt e ka fetola kapele bophahamo ba PIN ea PCB ka botenya bo fapaneng.

● Sesebelisoa sa Ts'ebetso

Ho sebelisa sebopeho sa ts'ebetso ea Windows XP, 'me ho bonolo ho ithuta ho mosebelisi, ka mohopolo o sebetsang oa mochini o sebetsang hantle.Programi ng e entsoe ka mosebetsi oa ho ruta le ho tsamaisa, tataiso e fumaneha mohatong o mong le o mong.Chinese/Englishselectable Operating Journal/Breakdown Record/Breakdown Diagnosis

● Tlhahlobo le Tlhahlobo ea Boleng ba Khatiso ea 2D Paste

Netefatsa boleng ba khatiso ea sehlahisoa, Karolo ena e ka lemoha kapele bakeng sa khatiso ea offset, peista e sa lekaneng, e sieo le borokho le liphoso tse ngata.