Lihlahisoa

Selective wave soldering (S-455)

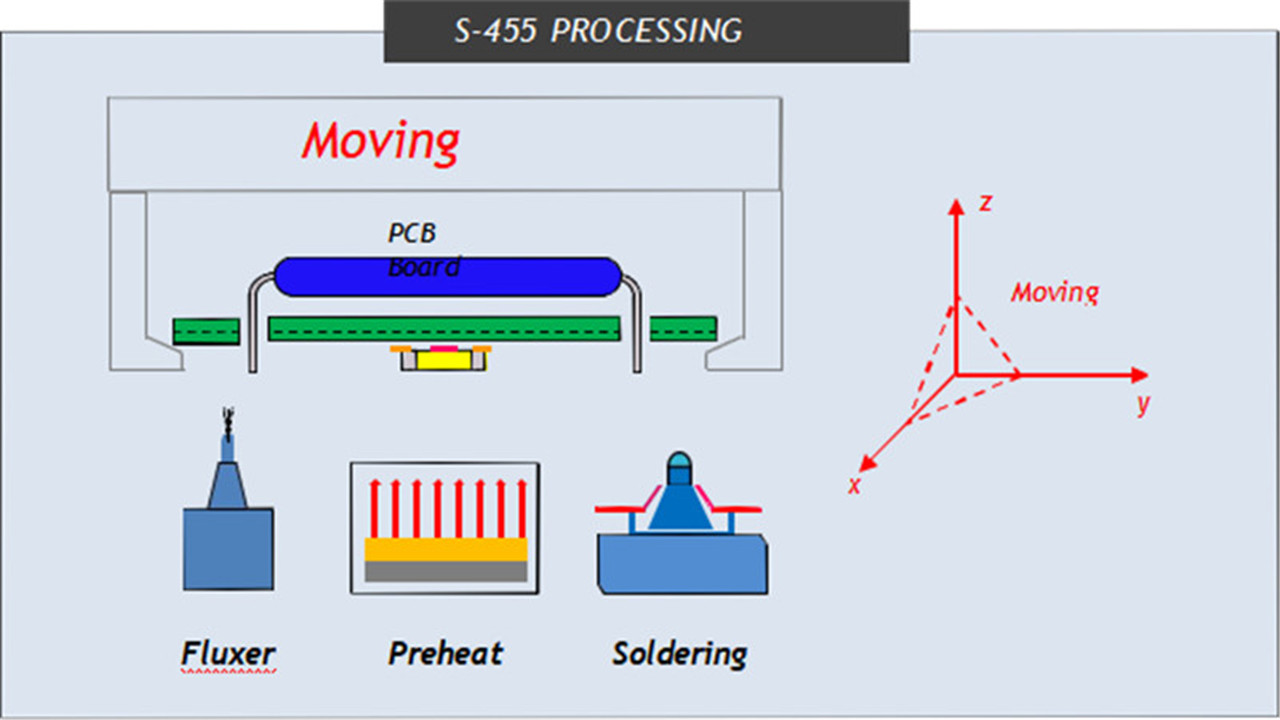

Mokhoa oa tsamaiso

Pcb loading manual

PCB fallela preheating zone's top bakeng sa

Tsamaisa ka holim'a nozzle ea fluxer e nang le tsela ea ho seta

PCB tsamaea ka holim'a solder nozzle le

Ho laolla ka letsoho

Molemo ka ho fetisisa

● Kaofela mochining o le mong, tafoleng e ts'oanang ea ts'ebetso ea XYZ e kopanya fluxing le soldering, compact & tshebetso e feletseng.

● PCB board movement, fluxer nozzle le solder pitsa e tsitsitseng.boleng bo phahameng ba soldering.

● E ka sebelisoa ka thōko ho mohala oa tlhahiso, e bonolo bakeng sa ho etsa mohala oa tlhahiso.Taolo e felletseng ea PC.Likarolo tsohle li ka kenngoa ho PC 'me tsa bolokoa ho menu ea PCB, joalo ka tsela e tsamaeang, mocheso oa solder, mofuta oa flux, mofuta oa solder, mocheso oa n2 joalo-joalo, bokhoni bo botle ba ho lekola le ho fumana boleng ba solder bo bonolo.

Mochini o tloaelehileng o kenyelletsa

| Seriale | Ntho | Ntho | Bongata |

| 1 | Tsamaiso ea ho laola | PC & hlokomela | 1 sete |

| Phela ka k'hamera ea ho shebella | |||

| taolo ya motsamao | |||

| 2 | Tafole ea Motion ea PCB | tafole ea motsamao oa xyz | 1 sete |

| axis e nang le screw screw & linear guild rail | |||

| 3 axis e nang le servo motor & driver | |||

| 3 | Sistimi ea fluxing | Jetting valve e tsoang kantle ho naha | 1 sete |

| tanka ea metsi | |||

| tsamaiso ea methapo ea mali | |||

| 4 | tsamaiso ea ho futhumatsa pele | IR heater ka tlase | 1 sete |

| 5 | Pitsa ea soldering | Pitsa ea solder ea 15kg, impeller, kotopo, enjene ea seva | 1 sete |

| mocheso oa solder holim'a tsamaiso ea alamo ea mocheso | |||

| tsamaiso ea ho laola mocheso oa solder | |||

| Sistimi ea ho futhumatsa e ka hare ea N2 | |||

| (Boemo ba ka hare: 4mm x 3pcs, 5mm, 6mm) Nozzle ea solder e tloaelehileng | |||

| 6 | Sistimi ea conveyor | PCB side clampingsystem | 1 sete |

| 7 | Chese ea mochini | mochini foreime/sekoahelo & penta | 1 sete |

Tlhaloso ea mochine

Karolo ea 1: Software

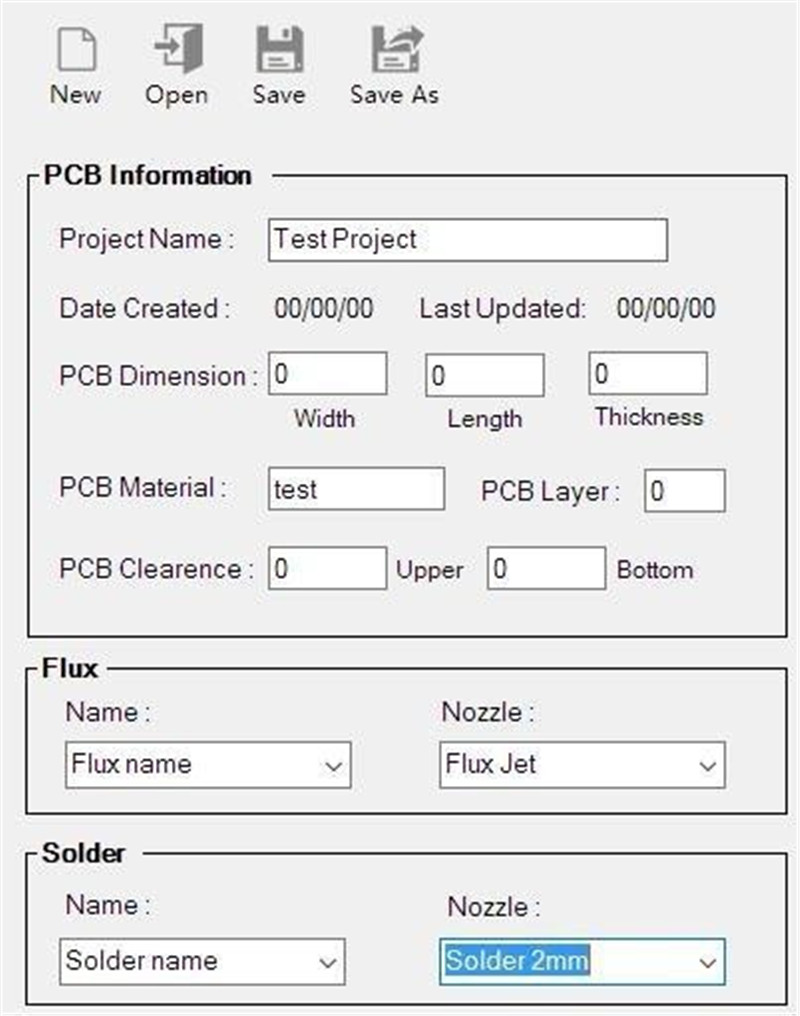

Sistimi eohle ea software e ntlafalitsoe ho latela sistimi ea Windows7, e nang le bokhoni bo botle ba ho latela mohlala.

Sebelisa sets'oants'o se sekenoeng e le bokamorao bakeng sa mananeo a tsela, lebelo le sisinyehang, nako ea ho lula, lebelo le se nang letho, bophahamo ba Z, bophahamo ba maqhubu joalo-joalo kaofela li etselitsoe sebaka sa marang-rang se fapaneng.

Hlahisa ts'ebetso ea solder ka khamera e hlahang.

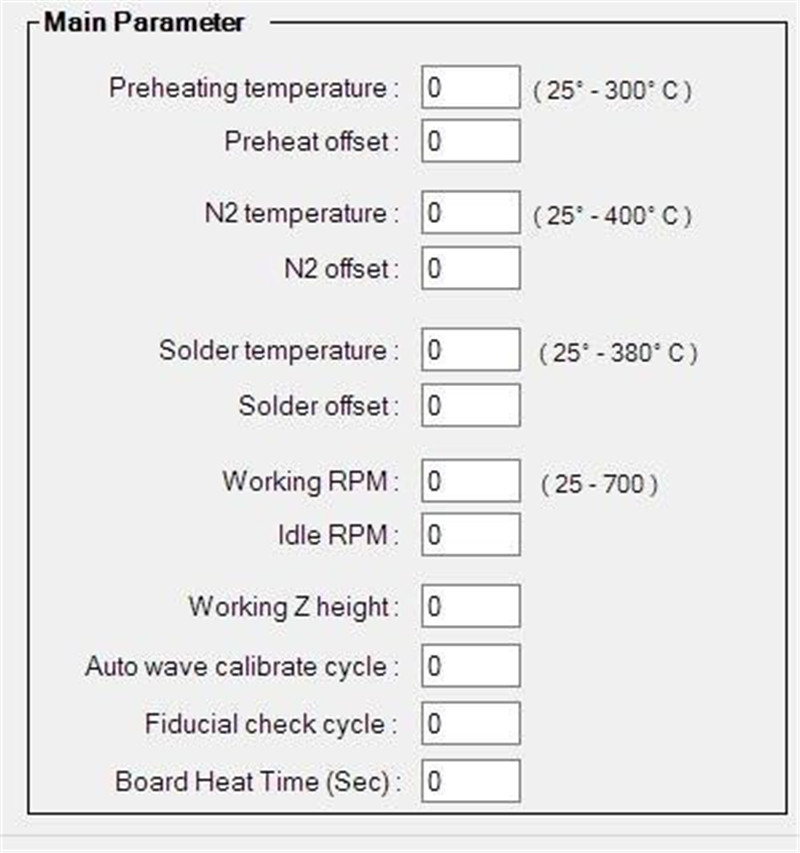

Mekhahlelo ea bohlokoa e tlas'a leihlo ka botlalo ke software ea PC, joalo ka mocheso, lebelo, khatello joalo-joalo.

E ka ntlafatsoa hore e be le ts'ebetso ea calibration ea auto wave height, ho hlahloba le ho lekanya bophahamo ba maqhubu ka mor'a pcb e 'ngoe le e' ngoe e itseng, kahoo ho boloka botsitso bo botle haholo ba maqhubu.

Na ntlafatswa ho ba le Mark boemo ba mosebetsi, ho hlahloba PCB e letshwao ntlha ka mor'a hore mong le e mong pcb itseng, kahoo ho fokotsa boemo ba pcb ea.

Mabapi le menu ea PCB mochining oa solder, tlhahisoleseding eohle e tla kenngoa faeleng e le 'ngoe.E tla kenyelletsa boholo ba PCB le setšoantšo, mofuta oa flux o sebelisitsoeng, mofuta oa solder, mofuta oa solder nozzle, mocheso oa solder, mocheso oa N2, tsela ea tshisinyo le bophahamo ba leqhubu la sebaka se seng le se seng le bophahamo ba Z joalo-joalo. mabapi le hore na e etsoa joang historing, hape ho bonolo ho e fumana.

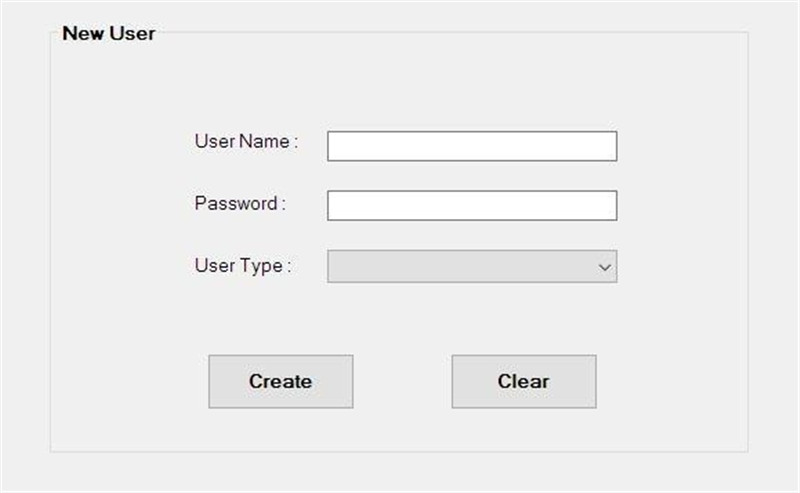

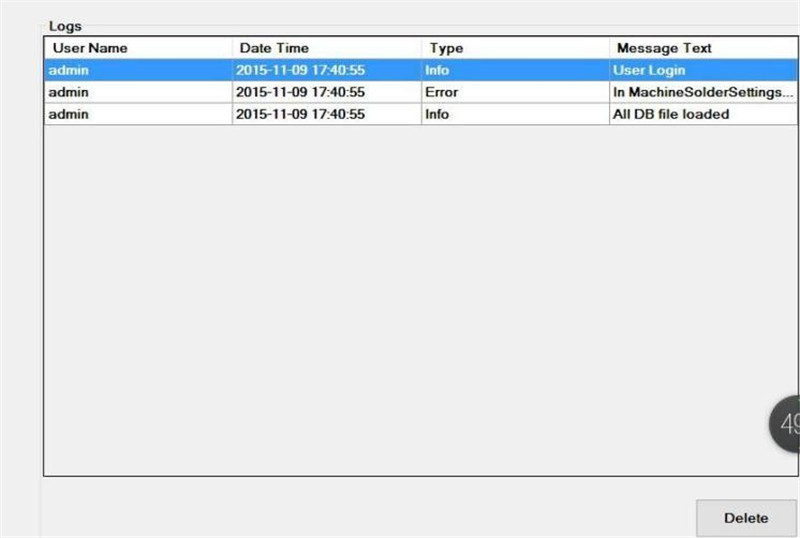

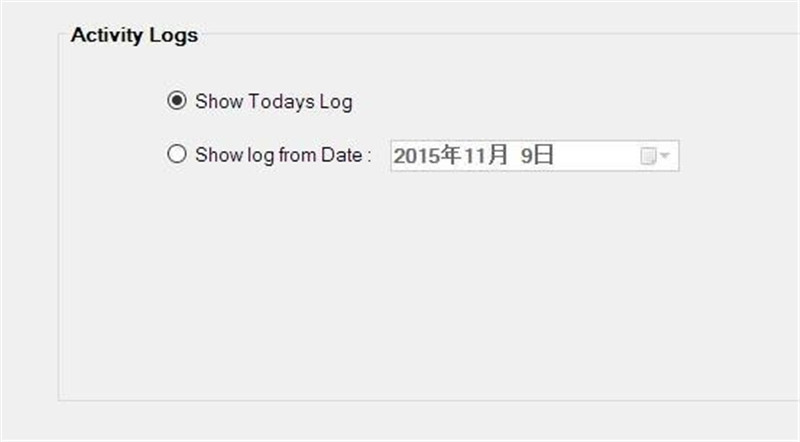

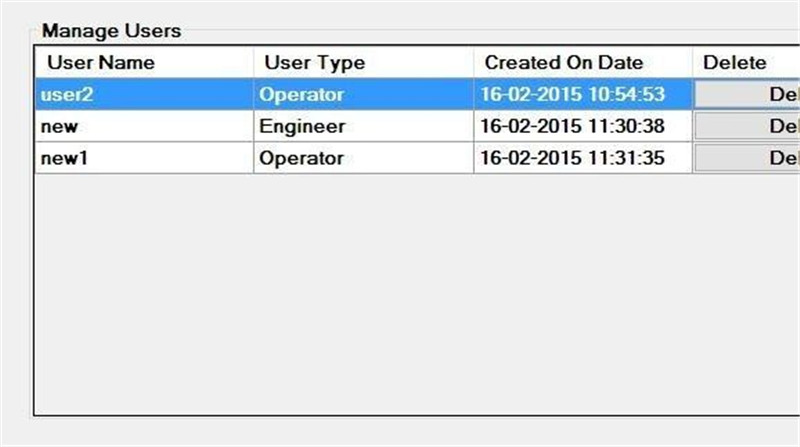

Ka ts'ebetso ea LOG, fana ka maemo a 3 ho kenya software e nang le litokelo tse fapaneng.Ho sa le joalo, e ka rekota ts'ebetso ea mochini le alamo.

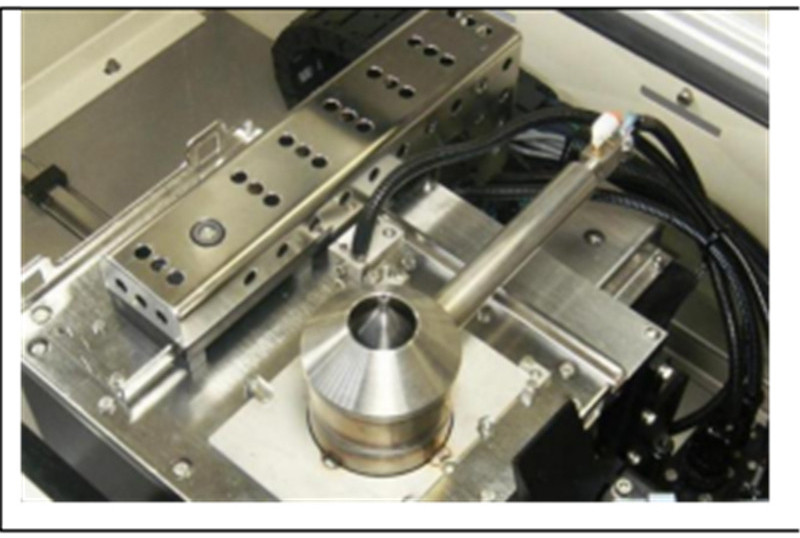

Karolo ea 2: Sistimi ea Motion

Tafole ea Motion e ne e etselitsoe motheo oa mohopolo oa mabone.

Panasonic servo motor & driver fana ka matla a ho khanna a tsitsitseng, screw pole & linear guild seporo bakeng sa tataiso.Boemo ba bohlokoa, lerata le fokolang, motsamao o tsitsitseng.

Ka poleiti e thibelang lerole ka holim'a tafole e sisinyehang, kahoo ho qoba flux kapa solder drop ho senya screw ea bolo.

Karolo ea 3: Sistimi ea Fluxing

Tekanyetso e nang le valve ea jet ho fumana sephetho sa boleng bo holimo ka letheba le lenyenyane la flux.Flux e na le tanka ea khatello ea polasetiki ea PP, etsa bonnete ba hore khatello e tsitsitse ntle le tšusumetso ea bongata ba phallo.

Karolo ea 4: Preheat

Preheating e ka tlase e na le mochini o tloaelehileng, Position e ka fetoha.

Karolelano ea mocheso e ka fetoloa ke PC, ho tloha 0 ---100%

Karolo ea 5: Pitsa ea Solder

Thempereichara ea solder, mocheso oa N2, bophahamo ba maqhubu, calibration ea wave joalo-joalo kaofela li khona ho kenya software.

Pitsa ea solder e entsoe ka Ti, eseng ho lutla.E na le heater ea tšepe ka ntle, e matla ebile e chesa ka potlako.

Pitsa ea solder e hoketsoe ka sehokelo se potlakileng.Ha o fapanyetsana pitsa ea solder ntle le ho kenya mohala hape, feela plug le ho bapala.

Sistimi ea ho futhumatsa ea N2 inthaneteng, ho kolobisa solder ka mokhoa o phethahetseng le ho fokotsa manya a solder.Ka ho hlahloba boemo ba solder & alamo.